Executive Summary

The Buildings and Construction industry is a significant contributor to global CO2 emissions. Accurate environmental impact data is required to enable decision-makers to implement measures to reduce this impact. For this reason, the demand for product environmental information that allows for comparisons between products and manufacturers is increasing. By providing public access to aggregated product environmental impact data, Environmental Product Declarations (EPDs) are a step in the right direction.

EPDs communicate the results of third-party verified product Life Cycle Assessment (LCA) studies for multiple environmental impact categories, such as climate change and resource depletion. There is still work to be done in terms of harmonisation of the methods used in the underlying LCA studies of EPDs; however, this is not unique to the Buildings and Construction industry. The harmonisation of methods behind LCA studies is an ongoing challenge, as work towards consensus continues.

While EPDs of the same product that have applied different methods are often incomparable, the data presented in EPDs enables decision-makers to make better-informed decisions that can contribute positively to broader sustainability goals. Until harmonisation and consensus are achieved, transparent reporting on how the results of an EPD can and cannot be used can help non-LCA experts identify incomparable EPDs and ensure decisions lead to reduced impacts.

AESG is a leading specialist consultancy that offers a specialised and qualified team to facilitate the process of preparing and publishing EPDs for manufacturers of building and construction products. With experts in Life Cycle Assessment (LCA), AESG also provides the full LCA study to the manufacturer along with recommendations on where further environmental reduction measures may be applied.

As experts in sustainability, AESG further works closely with suppliers and developers, facilitating the process towards achievement of project sustainability targets and certifications throughout all design stages of building and infrastructure projects.

1 Introduction

The Buildings and Construction industry is a significant contributor to global carbon dioxide (CO2) emissions. The International Energy Agency (IEA) reported that the industry accounted for approximately 37% of global operational and process-related emissions in 2021 (UNEP, 2022). Process-related emissions are emissions associated with the manufacturing process for a building product, such as concrete or steel. This includes the emissions from the extraction of raw materials and from the production of materials and energy used within the manufacturing process. Process-related emissions account for approximately 9% of the 37% of global operational and process-related emissions (UNEP, 2022), and can be quantified using Life Cycle Assessment (LCA).

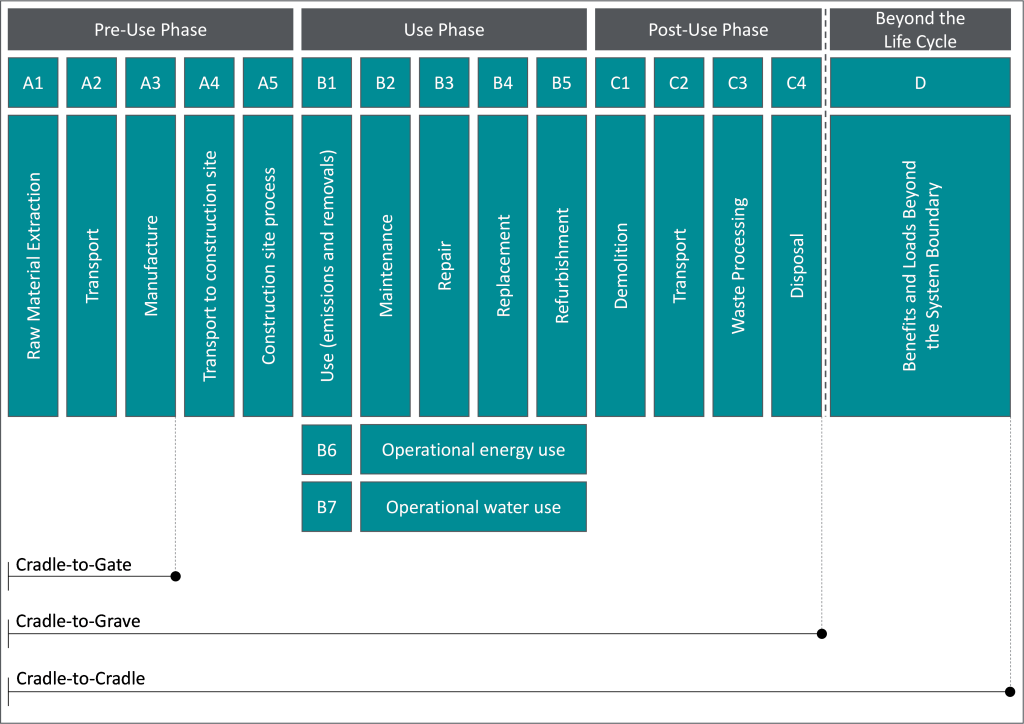

LCA, as defined within the international standards, is the compilation and evaluation of the inputs, outputs, and the potential environmental impacts of a product system throughout its life cycle (ISO 14044:2006). Figure 1 depicts the life cycle stages that may be included within an LCA. As indicated in the figure, LCA can be conducted from cradle-to-gate (such as to the end of the manufacturing process), as well as from cradle-to-grave or cradle-to-cradle. The life cycle stages to be included are defined during the first step of an LCA study, along with the specific system boundary inclusions and exclusions.

Figure 1: Life Cycle Stages

A variety of environmental impact categories can be assessed with LCA, including climate change, acidification, eutrophication, photochemical ozone formation, and resource depletion (metals/minerals), to name a few. For a holistic assessment, multiple impact categories should be evaluated to avoid burden-shifting from one impact category to another. In other words, if focus is placed on one impact category (such as climate change), implementation of reduction measures for this impact category may result in an increase in another impact category (such as resource depletion – metals and minerals). By including multiple impact categories in a study, burden-shifting can be identified and avoided or optimized.

LCA has been used across multiple sectors to inform decision-making and policy development. There are international standards that should be complied with when conducting an LCA study, being ISO 14040:2006 and ISO 14044:2006. These standards are guidelines that present the steps of an LCA and the methodological choices. The flexibility in these standards allows for LCA to be applied across industries, however, the standards are also criticized for being too vague leading to inconsistent application of methods and results that are incomparable. For this reason, additional standards based on these international standards have been developed with the aim of harmonising the methodological choices for product categories. The intent of harmonisation of the methods is to enable valid comparisons within these product categories.

One such standard is the international standard, ISO 14025:2006. This standard provides the procedures for developing Environmental Product Declarations (EPDs) as well as guidance on the development of Product Category Rules (PCRs). An EPD communicates the results of third-party verified product LCA studies, whereas PCRs provide the methods that the LCA study must comply with. Within the Buildings and Construction industry, international and European PCRs have been developed for building and construction products. This includes ISO 21930:2017 and EN 15804:2012. These standards provide the core rules for EPDs of construction products and services. However, in attempts to further harmonise the methods applied, additional standards, referred to as complementary Product Category Rules (c-PCR), have also been developed that are product specific. For example, c-PCRs for Concrete and Concrete Elements (EN 16757:2022) and for Concrete Batching Plants have been published by the International EPD System.

Within the Buildings and Construction industry, EPDs are commonly used to communicate LCA results. There are benefits and challenges to the use of EPDs in the decision-making context, which will be discussed in more detail in Section 3. First, the following section describes the general process for verifying and publishing an EPD.

2 EPDs – Verification and Publication

As mentioned in the previous section, there are multiple standards that have been developed, all with the aim of harmonising LCA methods and thereby allowing for valid comparisons to be made across studies. This gets slightly more complicated when including Programme Operators in the picture.

Programme Operators (POs), such as the International EPD System, are the verification and publication bodies for EPDs. There are multiple POs worldwide, with approximately 18 across Europe (Konradsen et al, 2023). Each PO is required to publish General Programme Instructions (GPI) that provide further details on the methods to be followed for the LCA study as well as the procedure for the verification process.

The underlying LCA study for the EPD is often conducted by an LCA practitioner and must comply with the international or European standards as well as the PCR and GPI. The practitioner must be in contact with the PO prior to conducting the LCA in order to understand the methods that must be followed according to the documentation provided by that PO. POs can publish their own PCR and c-PCR. These are not harmonised across POs, and therefore, the use of different POs for an LCA study on the same product can lead to different and incomparable results.

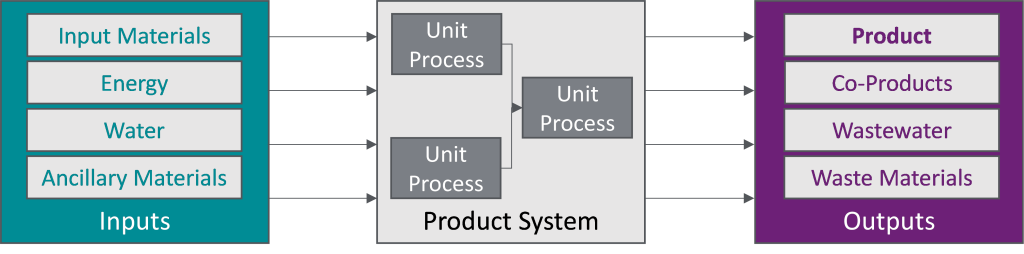

Once the PCR or c-PCR that will be followed for the LCA study has been identified, the assessment is conducted. This assessment includes the collection of specific data from the manufacturing process of the product being assessed, including the materials used as well as the energy and fuels consumed. Allocation methods are also applied in accordance with the standards for any co-products that are generated. This includes the possibility of applying allocation of the environmental impacts by mass or economic value between the product of interest and the co-products. Figure 2 depicts in general the input and output data collected for each unit process within the product system from the manufacturer. A unit process is the smallest process for which data is collected. All inputs and outputs of the system are compiled into an LCA model, which can be a time-consuming process dependent on the complexity of the manufacturing process steps and the availability of data.

Figure 2: General Inputs and Outputs for the Product System

Since an LCA study is conducted from the ‘cradle’ (raw material extraction), background databases are used to fill in the data gaps on, for example, the environmental impacts of the production of chemicals or electricity used within the manufacturing process itself. Once the LCA model is developed, the overall environmental impact of the product being assessed is calculated. A report is prepared in the EPD format and is sent along with all supporting documentation to the PO for third-party verification of the LCA, and publication as an EPD. The final published EPD does not contain confidential data related to the manufacturing process itself, but reports the final aggregated environmental impact results in the unit of each impact category assessed (for example, kg CO2-equivalent per unit of product for the climate change impact category).

3 EPDs – Benefits and Challenges

The demand for Environmental Product Declarations (EPDs) within the Buildings and Construction industry is increasing. According to Gelowitz and McArthur (2017), the release of LEED version 4 has resulted in the initial increase in the number of EPDs published for the construction sector, as well as an increase in POs and developed PCRs and c-PCRs.

There are key benefits to the use of EPDs. They offer a standardised format for presenting aggregated environmental information and are publicly available. Published EPDs may help consumers and end-users make better-informed decisions that consider the environmental impact of the product being purchased. For example, results from EPDs can be used to make recommendations to building contractors regarding procurement of products with lower environmental impact. By favouring products with lower environmental impact, manufacturers are encouraged to develop more sustainable alternatives, which may drive innovation within the industry.

However, a key challenge of the use of EPDs is comparability. In order to correctly determine if one product has a lower environmental impact over another, EPDs of similar products must be comparable. With the variation in methods that can be applied, this is not always the case, which may lead to the selection of a product that does not necessarily have a reduced impact. Furthermore, the consumer or end-user must have the knowledge to correctly interpret and compare the EPD results from one study to another. These results are not necessarily presented in a user-friendly way for non-LCA experts, although EPDs are publicly available documents used in decision-making.

Work is being done to further harmonise the methodologies behind the LCA studies of EPDs in order to ensure comparability. One recommendation is to move towards one centralised PO (Konradsen et al, 2023). While this could be one part of the solution, the ability to come to a consensus on how to conduct an LCA study has a history of not being a simple task. For this reason, transparency in reporting the methods used, along with a thorough interpretation of the results and how they can and cannot be used in the decision-making context is vital.

EPDs do outline the main methods that have been followed along with a disclaimer that EPDs from different POs may not be comparable. However, more is required to ensure their appropriate use. In parallel to improvements in method harmonisation, EPDs should move towards including transparent results interpretation (sensitivity analysis and an uncertainty statement) in an understandable way and highlight within the report how the results are to be used.

4 Summary and Outlook

The demand for product environmental information for building and construction products is increasing. The Buildings and Construction industry is a significant contributor to global CO2 emissions, and consumers and end-users require accurate information to be able to make informed decisions based on environmental impact. EPDs are a step in the right direction, providing public access to aggregated product environmental impact data. Through the data presented in EPDs, project managers are equipped to make better-informed decisions that can contribute positively to broader sustainability goals.

However, there is still work to be done in terms of harmonisation of the methods used in the underlying LCA studies of EPDs. There are multiple standards that have been published based on the international standards for LCA (ISO 14040:2006 and ISO 14044:2006) in attempts to further harmonise the methods applied. POs have further published their own standards for products, which are not harmonised across POs. The use of different methods across POs has resulted in EPDs of similar products that are incomparable. Research is continuing in this area to reach a consensus within many industries, thus the challenge spans beyond the Buildings and Construction industry.

In the meantime, transparency in reporting LCA results and methods within EPDs in an understandable way to non-LCA experts can help ensure the appropriate use of EPD data. By outlining how the EPD results can be used, consumers and end-users are better equipped to identify cases where EPDs may or may not be comparable. With this, clarity is provided, and EPDs can move further towards accomplishing their initial aim of permitting comparability within product categories and being a useful tool for decision-making.

How AESG can help

AESG offers a specialised and qualified team that will facilitate the process of preparing and publishing EPDs. With experts in LCA, the process from data collection through to the final LCA results is seamless. Along with the final EPD report, AESG provides the full LCA study to the manufacturer with recommendations on where further environmental reduction measures may be applied.

As an international consultancy, engineering and advisory firm with offices in London, Dubai, Abu Dhabi, Riyadh, Singapore, South Africa, Al Ula and Al Madinah, AESG is well-connected with suppliers and developers. AESG works closely with developers, providing recommendations for reduction of project environmental impacts and successfully facilitating the process towards achievement of project sustainability targets and certifications throughout all design stages. AESG further ensures the correct use of EPDs by providing recommendations for procurement of alternative products with lower environmental impacts, where sufficient data exists.

At AESG, we pride ourselves in being leaders in the industry in each of the services that we offer. We have one of the largest dedicated teams with decades of cumulative experience in life cycle assessment, carbon management, sustainable design, sustainable engineering, fire and life safety, façade engineering, commissioning, waste management, environmental consultancy, digital delivery, cost management, strategy and advisory and acoustics.

Carbon Specialist, AESG

Dr. Deidre Wolff is working as part of the Sustainability team at AESG as a Carbon Specialist. Here she conducts Life Cycle Assessment (LCA) studies of commercial and residential buildings and infrastructure. With 8 years of experience working with academia and industry, Deidre further oversees the execution of all AESG Environmental Product Declaration projects. She has led and delivered several product LCA studies across a variety of sectors. Throughout her work experience, Deidre has collaborated with multiple international partners, breaking down LCA results and providing recommendations. She has further developed specific methodologies and models for carbon assessments, particularly focused on infrastructure. Deidre completed her PhD thesis at Technological University Dublin, which focused on the development of an uncertainty management methodology for LCA applied to the built environment. Deidre further has a Master of Science in Sustainable Energy and Green Technologies from University College Dublin and a Bachelor of Science in Chemistry from Simon Fraser University.

For further information relating to specialist consultancy engineering services, feel free to contact us

References

EN 15804:2012+A2:2020, Sustainability of construction works – Environmental product declarations – Core rules for the product category of construction products

Gelowitz, M.D.C., McArthur, J.J. (2017). Comparison of type III environmental product declarations for construction products: Material sourcing and harmonisation evaluation. Journal of Cleaner Production 157, 125-133, https://doi.org/10.1016/j.jclepro.2017.04.133

ISO 14025:2006, Environmental labels and declarations — Type III environmental declarations — Principles and procedures

ISO 14040:2006+Amd1:2020, Environmental management — Life cycle assessment — Principles and framework

ISO 14044:2006+Amd2:2020, Environmental management — Life cycle assessment — Requirements and guidelines

ISO 21930:2017, Sustainability in buildings and civil engineering works — Core rules for environmental product declarations of construction products and services

Konradsen, F., Hansen, K.S.H., Ghose, A. et al (2023). Same product, different score: how methodological differences affect EPD results. Int J Life Cycle Assess, https://doi.org/10.1007/s11367-023-02246-x

United Nations Environment Programme (UNEP, 2022). 2022 Global Status Report for Buildings and Construction: Towards a Zero‑emission, Efficient and Resilient Buildings and Construction Sector. Nairobi