Achieving ambitious sustainability and decarbonization targets will inevitably require consultants and engineers to push boundaries to design the next generation of high-performance buildings. While this is essential it’s important to make sure we are achieving marginal gains across all systems and also to ensure that the buildings and systems we design consider their locality and the nuances of the climate in which they are to be built.

One area of HVAC design that can be over-looked is the sequence of operations provided for MEP systems which are a critical item that can have major impact on energy consumption but at very little additional cost to the project.

An example of this is the control routine for a Fresh Air Handling Unit (FAHU). Typically, in the UAE the primary concern of these units is to cool and dehumidify external air to conditions that do not impact the sensible control of the space but offset the latent gains from occupants, internal processes or infiltration of external air though the building envelope. It is common to sequence the FAHU to maintain a constant Fresh Air Temperature (FAT) after the FAHU cooling coil, typically at between 11.5 – 13.5 °C. Whilst this will ensure full dehumidification of the air protecting the internal spaces from the impact of High Relative Humidity, it is inefficient to “over-cool” the Fresh Air to this extent during periods when the ambient Moisture content is below targeted treated Fresh Air condition.

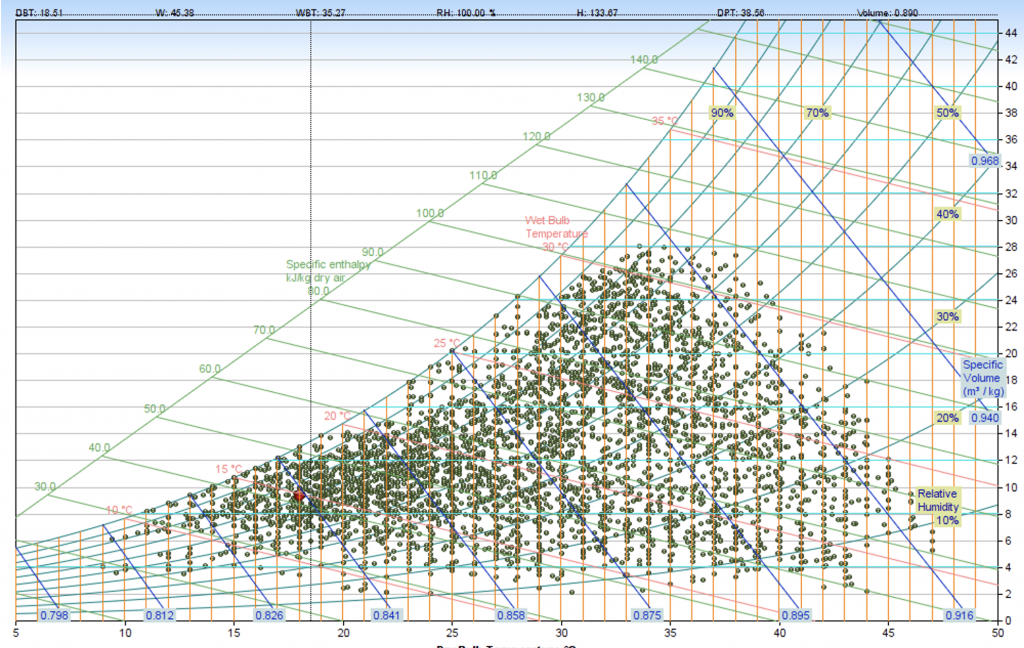

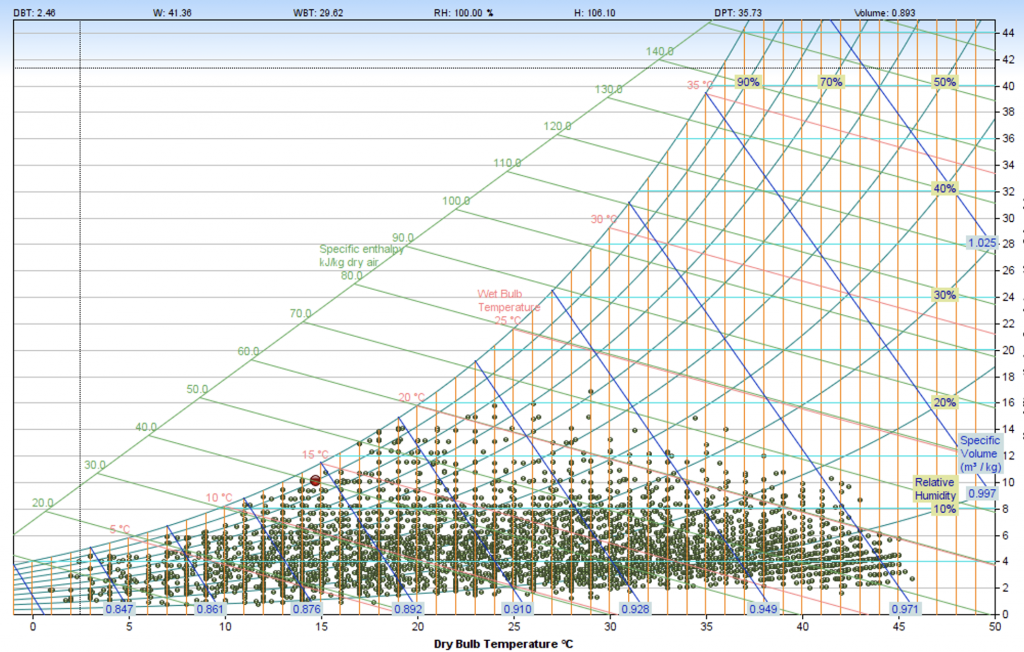

In the UAE this occurs predominantly in the winter months, however in areas of KSA which have a drier climate; such as Riyadh, significant portions of the year should benefit from a variable FAT control strategy that is based on the external air moisture content.

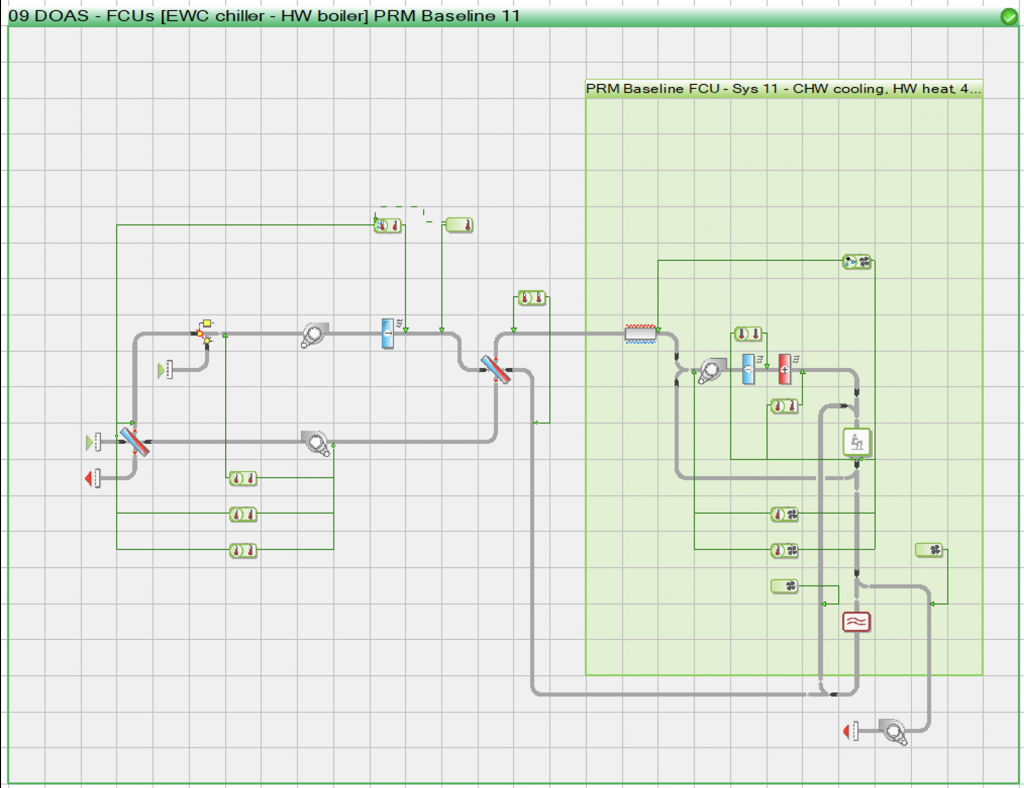

To validate this AESG prepared a study in IES VE using Typical Meteorological Year (TMY) weather data for 4 regional locations to determine what energy savings are possible by revising the controls and applying heat recovery on the supply side.

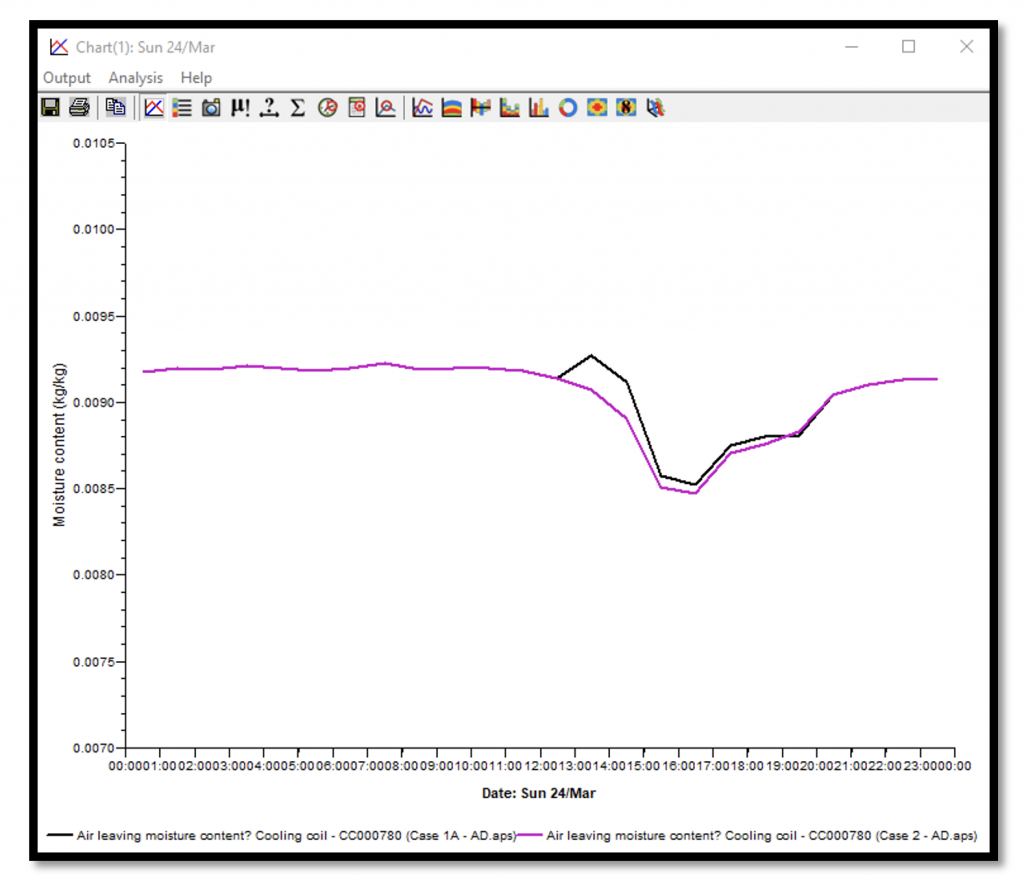

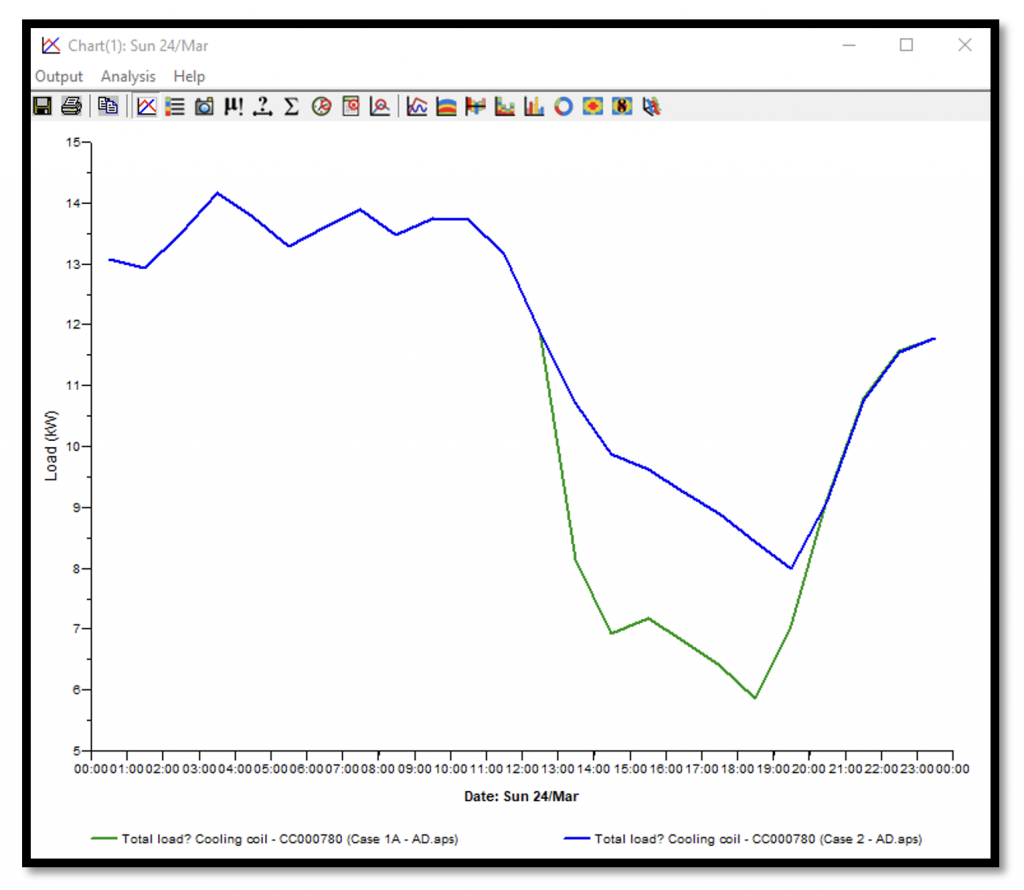

The baseline solution was taken as a Fresh Air Handling unit with a 2 stage heat recovery, the first an enthalpy wheel, the second a sensible wheel. The units were sized for 1 m3/s with a constant supply volume. The coil control was defined as 13 °C Dry Bulb with a coil contact factor of 0.91. The building considered was a simple office with usage patterns and occupancy typical for the region. These parameters and set points were not adjusted in the differing scenarios.

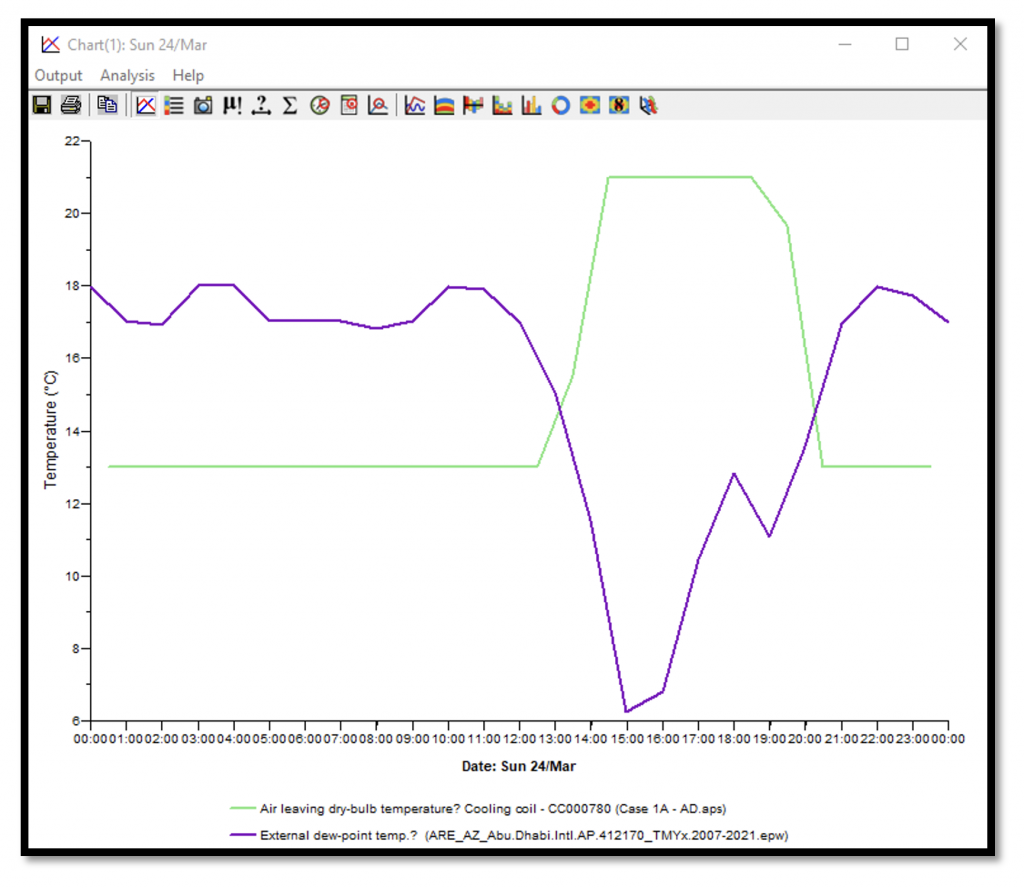

The revised control strategy utilizes dew point control to reset the FAHU FAT to eliminate over cooling such that when Ambient Dew Point (ADP) is above 13 °C the FAT is set to 13 °C but when the ADP is below the 13 °C the SAT is set to 21 °C.

In both cases the served spaces were considered as offices with typical profiles for occupancy and miscellaneous gains.

The results of the study are shown in the table below:

Annual FAHU Cooling Coil Loads (MWh)

| Riyadh TRY | Dubai TRY | Abu Dhabi TRY | Jeddah TRY | |

|---|---|---|---|---|

| Variable FAT | 52 | 125 | 121 | 137 |

| Constant FAT | 81 | 134 | 130 | 140 |

| Energy Saving % | 36.4% | 6.2% | 7.4% | 2.4% |

Full Building Annual Cooling Loads (MWh)

| Riyadh TRY | Dubai TRY | Abu Dhabi TRY | Jeddah TRY | |

|---|---|---|---|---|

| Variable FAT | 330 | 469 | 451 | 482 |

| Constant FAT | 359 | 477 | 461 | 486 |

| Energy Saving % | 8.1% | 1.8% | 2.1% | 0.7% |

Weather date sources: https://climate.onebuilding.org/

From the results above, it can be seen that in all cases a cooling load saving can be achieved by optimizing the FAT to consider ambient moisture content, the saving is particularly large for the Riyadh weather data set which has a much drier climate than any of the other locations considered.

However, even in the worst-case reduction of Jeddah the savings for a 1m3/s FAHU are 3 MWh of cooling annual. If we assume this is produced by a high efficiency Water Cooled Chiller with a Seasonal CoP of 5 the electrical savings could be 0.6 MWh per m3 of Fresh Air.

Key Takeaways:

If we are going to target a net-zero future, nothing can be left off the table when it comes to energy consumption discussions, engineers must challenge assumptions and “business as usual” in all areas to make sure we optimise our design and deliver high performance buildings, marginal gains are still gains! AESG Sustainable Engineering team can support your projects to deliver high quality engineering with low energy performance a core value and not just a “nice to have!”

How can AESG help?

AESG is a specialist consultancy, engineering and advisory firm with offices in London, Dubai. Riyadh and Singapore working on projects throughout Europe, Asia and Middle East. We pride ourselves as industry leaders in each of the services that we offer. We have one of the largest dedicated teams with decades of cumulative experience in sustainable design, fire and life safety, façade engineering, building commissioning and digital asset management, waste management, environmental consultancy, strategy and advisory, acoustics, cost management and carbon management.

Director of Sustainable Engineering, AESG

Nicholas is AESG’s Director of Sustainable Engineering. He is a Fellow of CIBSE with 14 years’ experience in the Middle East leading the Engineering teams in the design of high value projects across a range of sectors, particularly hospitality, residential, public amenities and retail. Nicholas has extensive experience managing large teams in multiple geographical locations with experience in the delivery of diverse projects from a 500,000m2 Hospital projects, signature buildings at the Expo 2020 site and an iconic Museum project currently under construction.

At every opportunity Nicholas has embraced low energy building design with sometimes pioneering use of a range of sustainable building techniques including natural ventilation, solar thermal, PV, Rain water recycling, concrete core cooling and advanced chiller system integrated controls. During his career he has led MEP teams to deliver multiple LEED gold and Platinum projects achieving major energy savings through carefully engineered solutions tailored to the specific project need. A focus on option selection and testing ensured all ideas were robustly assessed to deliver the sustainable, operational and commercial aspirations of the projects undertaken.

For further information relating to specialist consultancy engineering services, feel free to contact us